Magnetically Controlled Casting Process

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 10,010,933 | 07/03/2018 | 2010-032 |

Full Description

Background

Current casting methods that produce features in a solid material with rapid prototyping techniques require highly specialized and expensive equipment. Further, these types of equipment must be programmed before each casting to achieve the desired results. Also, these traditional casting processes are synthesized either through layer-by-layer deposition which can be very time consuming or by mixing non-soluble components together which leads to heterogeneities and reduction in performance.

Current Invention

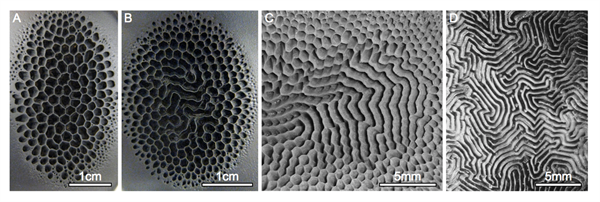

UCR Professor David Kisailus has developed an exciting one-step casting process that produces solid materials displaying controlled structural ordering into a wide range of sizes and shapes. The casting process utilizes a liquid material that is placed in a magnetic field and the liquid material solidifies over a ferrofluid resin/metal interface. The magnetic field allows for the ferrofluid to produce predictable and controllable patterns into the liquid material. The range of patterns generated includes honeycombs, labyrinths, spikes, ridges, and concentric rings.

Micrographs of structural diversity of final products obtained using the invention

Advantages

- The primary advantage for this invention is that it is a one-step process for the fabrication of the matrix compared to traditional methods for preparing composites that are either time consuming or lead to heterogeneities and reduction in performance.

- The process is carried out under relatively mild conditions thereby minimizing the need for costly capital equipment, waste disposal and labor costs - and therefore lower production costs

- The ability to control the casting process, ,

- Scalability of the casting process, and

- Ease of production.

Suggested uses

This casting process can fabricate molds that can be used in

- rapid prototyping;

- composite structural materials;

- complex energy storage devices; and,

- microfluidics.

Some of the materials that can be produced or grown in these molds include biological materials (i.e. cells, tissues), organic materials (i.e. polymers, chemotherapeutics), and inorganic materials (i.e. structural ceramics, catalysts, semiconductors).

Inventions by David Kisailus

See all of Prof. David Kisailus inventions at UCR

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

casting, magnetic, ferrofluid, molds, cells, tissues, polymers, chemotherapeutics, ceramics, semiconductors