Method For Producing High-Efficiency Thermal Materials With Graphene And Metal Fillers

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 9,716,299 | 07/25/2017 | 2013-156 |

Full Description

Background:

Thermal interface materials (TIMs) applied between heat sources and sinks are essential for thermal management in electronic, optoelectronic, photonic devices and systems. Conventional TIMs have thermal conductivities in the range of ~1 – 5 W/mK at room temperature and require significantly high volume of fillers (~ 50%). Carbon nano tubes are an attractive option due to their high intrinsic thermal conductivity but have not been practical because of either their challenges in coupling with the matrix material or prohibitive cost.

Technology:

Prof. Alex Balandin and his research team have developed and demonstrated a novel use of liquid phase exfoliated graphene and multi-layer graphene (MLG) as fillers in TIMs. The graphene-MLGs as fillers were tested with a variety of TIMs such as epoxy, grease and composites with metal particles. The tests demonstrate significant increase in thermal conductivity.

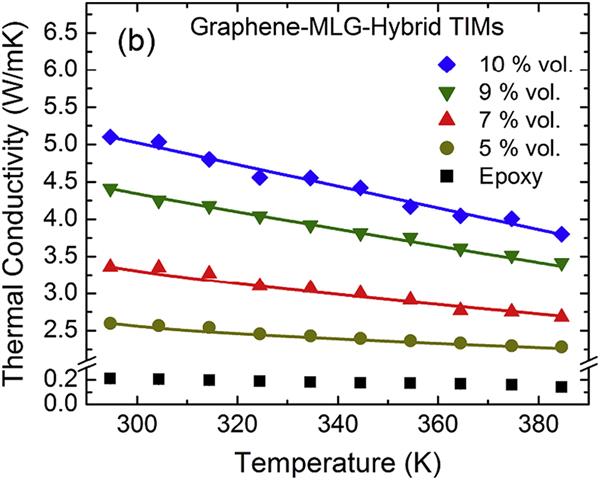

Measured dependence of the thermal conductivity of TIMs on temperature for different loading fractions.

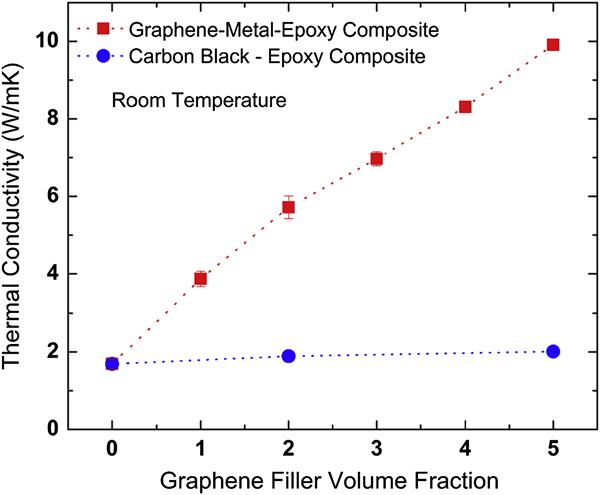

Thermal conductivity of the pristine silver epoxy, hybrid graphene–FLG–silver-epoxy composites and the reference silver epoxy–carbon black composites

Advantages

The significant benefits of this invention are:

- The liquid exfoliation method for producing graphene-MLGs is inexpensive and can be implemented at an industrial scale.

- Thermal conductivity enhancements increased by a factor of ~23 for a graphene-MLG loading of 10%.

- Thermal conductivity of ~ 14 W/mK obtained with the addition of only 2% of the graphene-MLG mixture in commercial thermal grease.

- Low coefficient of thermal expansion and increased mechanical strength.

Suggested uses

- Reduction of thermal fatigue in EV batteries

- Improving device reliability and overall life of electronic and LED devices.

- Thermal management to enhance life and efficiency of photovoltaic cells.

- Variety of thermal management needs in automotive, communication as well as aerospace and defense.

State Of Development

Prototype samples and composite TIMs developed and tested in the lab.

Related Materials

Inventions by Prof. Balandin

Please review all inventions by Prof. Balandin and his team at UCR.

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

graphene, thermal interface materials, thermal, electronics, batteries, heat, thermal management, thermal conductivity