Multilayer High Density Microwells

Brief Description

Researchers at UC Irvine have developed high density, three dimensional (3D) micro-reactors for digital biology applications. The high-density imaging arrays overcome drawbacks associated with existing high density arrays fabricated on a single surface and the more recent 3D droplet emulsion arrays.

Full Description

A continual need for high density microwell plates or micro-reactors exists, and therefore work has been done to fabricate an array of sites or wells within a single surface. Although densities have become high, they are often limited by pattern formation and manufacturing techniques with often limited well height to width aspect ratios on only a single planar surface. As a result, a large usable area between the microwells is lost depending on the pitch or spacing between adjacent wells. As the footprint of the microwell size is reduced to accommodate even higher densities, the ratio of usable microwell area to dead space decreases exponentially resulting in even greater loss of usable area on the imaging plane for high density microwell reactors. The density loss due to well spacing must be minimized or eliminated to achieve higher densities.

In addition, limits in the manufacturability of high aspect ratio microwells makes it prohibitive to increase reactor densities beyond a certain value as it begins to adversely affect the possible reactor volumes or imaging resolution. Also, it is prohibitively difficult to fill each microwell reactor as the aspect ratio increases due to the dominant effects of surface tension at such small length scales. This prohibits fluid from reliably filling each reactor well completely.

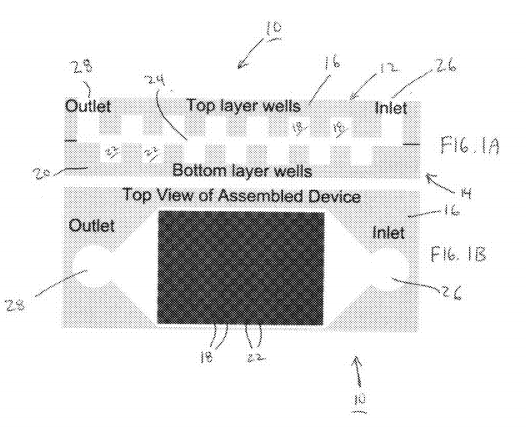

To address the aforementioned limitations, researchers at UC Irvine have developed a multilayer high density well array that increases the density of microwell array dramatically. Example of the device is shown in Figure 1.

Figure

1 shows an example of a multilayer well device created by the inventors.

The multiwall device comprises of multi-layers of complementary nanowells aligned and stacked upon each other. The well size can be fabricated and tuned to the size needed by a particular application. Furthermore, wells of different shapes (Squares, hexagons, octagons, and circles) can be fabricated. This results in an up to two-fold increase in reactor array density.

To fill the multilayer well device, the first fluid is flowed into the inlet and allowed to wet the wells. Bubbles are allowed to outgas, and a second immiscible fluid such as a light-mineral oil is injected to seal the first aqueous fluid inside each well.

The transparent nature of the device allows for optical imaging of the wells with little loss of information. The refractive indices of the microfluidic fluids and materials can be tuned to reduce lensing effects, both refractions, and reflections, to further reduce background noise levels, and loss of light intensity.

Suggested uses

This technology has applications in individual analysis of cells, organisms, or molecules, with applications such as polymerase chain reaction (PCR) or quantification. This technology dramatically increases the density of microwell arrays and allows real-time observation for digital microfluidic applications.

Advantages

This technology boasts high packing density with efficient usage of space. The multilayer well device increases the reactor density/area by using 100% of the imaging plane and increasing reactor density by as much as two-fold by allowing partial overlap of reactor wells.

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 9,095,852 | 08/04/2015 | 2011-574 |

Contact

- Alvin Viray

- aviray@uci.edu

- tel: View Phone Number.