The Poor Man’s Trough: A Bench Top Motor Free Method To 3D Langmuir-Blodgett Films

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Published Application | 20240299975 | 09/12/2024 | 2023-980 |

Full Description

Background

Langmuir-Blodgett (LB) films are monolayer films that are deposited onto substrates. LB troughs provide an excellent way to deposit monolayer films onto substrates. LB trough designs have yet to fully eliminate the capillary waves and striations on deposited films caused by the vibration of motorized stages. Commercially available systems for LB films can provide smooth, precisely-controlled, and vibration-free film deposition. However, these systems are expensive.

Technology

Research team led by Prof. Luat Vuong at UC Riverside have developed an inexpensive and accessible, LB trough design that utilizes a 3D-printed drainage basin to compress monolayer films. The team has devised a system where the geometry of a 3D-printed drainage basin mechanically compresses the film as the liquid drains, eliminating the need for motorized barriers. The team also developed a mathematical formula that dictates the shape of the drainage basin.

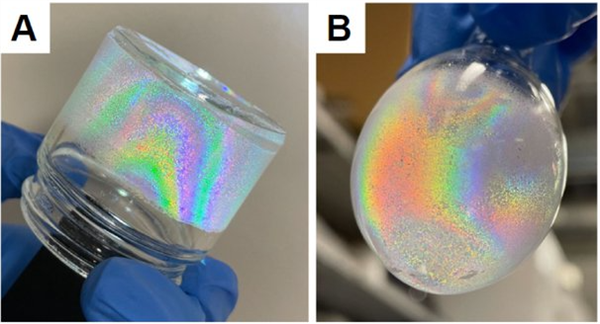

Sample polystyrene coatings on (A) a jar (4.2 cm diameter, 2 cm height) illuminated from LED light from above and inside of the jar; and (B) a bulb (3 cm diameter, 2.2 cm height).

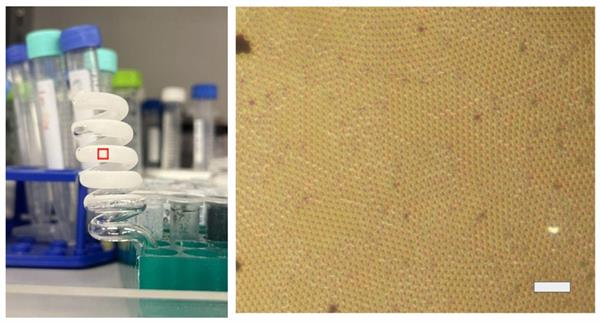

Microscope image of the 2 µm diameter polystyrene film that coats an outer edge of the compressor tube (red box, left). A high degree of order and monolayer packing of the film is shown on the right - scale bar 10 µm.

Advantages

- Cost effective and a more accessible approach that eliminates the need for expensive equipment.

- Demonstrated ability to produce close-packed films.

- Versatile in coating a variety of 3D objects.

- Ability to coat uniform, monolayer films.

- Ability to 3D print the drainage basin allows for customization and experimentation.

Suggested uses

For the fabrication of LB films used in a variety of applications including:

- Functional coatings

- Biological membranes

- Biosensors

- Anti-reflective glasses

Inventor Information

- Please see all inventions by Prof. Vuong and her team at UCR

- Please see recent press coverage of Prof. Vuong at UCR.

- Please visit Prof. Vuong's website to learn more about her team's research

Related Materials

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

langmuir-blodgett films, monolayer films, monolayer coatings, langmuir-blodgett troughs, metamaterials, interfacial self assembly, smart sensors, functional surfaces, anti-reflective glasses