In-Vacuum Front-Surface Type Irradiator (FROSTI) For Active Laser Wavefront Control

Full Description

Background

High-power laser systems are crucial for advanced manufacturing, scientific research and defense applications. The key limitation in these systems is the thermal distortion in their optical components. This distortion degrades beam quality, reduces precision, and limts the maximum operational power. Existing solutions to manage this heat are often complex, noisy, and insufficient for next generation applications.

Technology

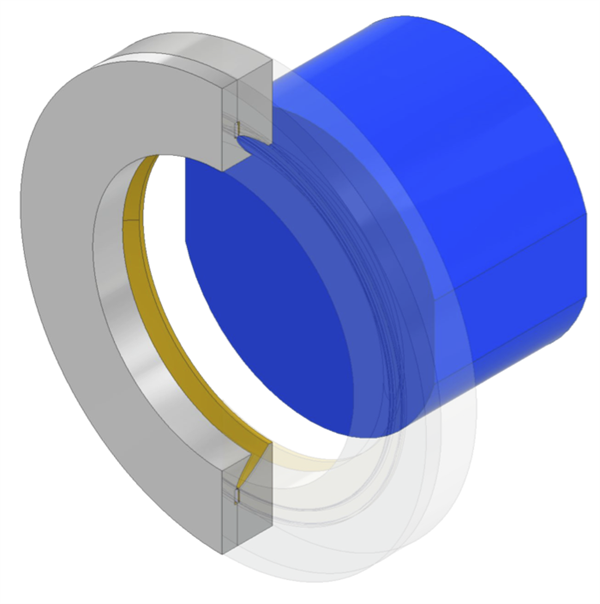

Prof. Jonathan Richardson and his team at UCR have developed an innovative thermal compensation system - the Front Surface Type Irradiator (FROSTI). The system applies a precise and stable heating pattern to the surface of the mirrors and lenses. The apparatus utilizes a novel, ring-shaped heater with advanced reflectors to radiatively heat the optical components, thereby actively correcting for thermal distortions in real-time. The approach ensures the optical surface maintains its perfect shape, even when subjected to megawatts of laser power.

Concept of FROSTI - Low-noise ring heater placed in front of a test mass reflective (HR) surface which applies the corrective heating pattern thereby bringing the test mass back to a "cold" optical state.

Advantages

- Minimizes wavefront distortions and thermal lensing to maintain high beam quality and power.

- Allows laser systems to operate at higher power without performance degradation.

- Utilizes blackbody radiation, which is significantly more stable and significantly less noisy than conventional heating systems.

- Provides precise temperature control to correct for nanoscale surface deformations.

- Suitable for use in ultra-high vacuum environments.

Suggested uses

- Scientific research - gravitational wave observatories (LIGO) and high precision metrology

- Industrial manufacturing - high-power laser cutting, welding and 3d printing

- Photolithography and wafer inspection

- Defense & Aerospace - directed energy systems and satellite communications

State Of Development

Proof-of-concept has been demonstrated, and device components have been fabricated and characterized at the lab scale.

Inventor Information

- Please read recent news coverage of Jonathan at UCR

- Please visit Jonathan's research group website to learn more about their research at UCR

Related Materials

Patent Status

Patent Pending

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

thermal compensation, high-power laser, optical distortion, ring heater, LIGO, precision optics, wavefront correction, directed energy