Micron-resolution malleable strain and pressure sensor

Brief Description

Scientists at UC Irvine have developed a sensitive, customizable, and user-friendly sensor for (1) strain detection as a result of cellular movement, (2) micro-fluidic device pressure detection, and (3) real-time monitoring of valve statuses in microfluidic chips. This research tool will provide new insights regarding cellular biophysics.

Suggested uses

·Strain sensing for in vitro microphysiological systems

·Real-time pressure sensing of valves in microfluidic devices

Features/Benefits

·New insights for in vitro biophysical properties of cells

·Soft, stretchable, water-proof make this sensor optimal for cell media and other aqueous environments

·Low-cost

·PDMS-based starting materials allow for easy customization and integration into other PDMS-based microfluidic devices

·Sensitive strain detection as low as 2.5µmeter displacement

·Sensitive uniaxial force detection as low as 20µNewtons

·Sensitive pressure detection as low as 400 Pascals

Technology Description

In vitro microphysiological systems (MPSs) allow scientists to better simulate the in vivo behavior of a tissue or organ to understand the complexity of its behavior. Cardiomyocyte, or heart cell, contractility is currently studied this way due to its implication in cardiovascular disease. Current methods of detecting contractility of cardiomyocytes include optical tracking or electronic tracking. Optical tracking is not great for long-term studies and requires heavy post-processing of acquired images. Electronic tracking measures the bending curvature of the substrate, which ultimately leads to an indirect measure of cardiomyocyte strain. The microfluidic devices used to carry out these experiments also lack effective methodologies to measure pressure and flow rate inside their channels, as opposed to solely at the inlet or outlet valves of these devices. Furthermore, these devices are expensive and hard to embed into microfluidic chips. Monitoring valve status has also been a challenge that requires high-speed cameras to monitor instances of valve opening or closure, which again requires extra image processing and time.

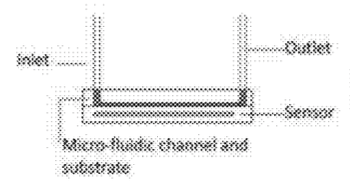

Researchers at UC Irvine have developed a strain sensor than can be embedded into current in vitro MPSs. The sensor can measure uniaxial force as low as 20µNewtons and continuously outputs an electronic reading, making it extremely user-friendly and offering time and cost-savings. It is also capable of measuring pressure that is applied on it, which can be leveraged for in channel pressure detection. It can also monitor the extent of valve opening such as 0, 3, 6, 9, 12ps for microfluidic devices. Its PDMS base (elastomer with excellent optical, electrical, and mechanical properties) allows for easy customization and integration into current microfluidic chips. Overall, this sensor offers various performance, cost-saving, and time-saving benefits relative to current technologies and can be easily implemented into MPS workflows.

State Of Development

Working prototype

Related Materials

Patent Status

Patent Pending

Contact

- Alvin Viray

- aviray@uci.edu

- tel: View Phone Number.

Inventors

- Chu, Michael

- Hui, Elliot

- Khine, Michelle

- Nguyen, Thao

- Werner, Erik

- Zhou, Yongxiao