Silicon From Waste Glass For Energy Storage Applications

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 11,367,869 | 06/21/2022 | 2016-703 |

Full Description

Background

According to the US Environmental Protection Agency, 5.4 million tons of glass containers ended up in landfill (in 2018) although glass containers are recyclable. Silicon is considered to be the next generation alternative to current graphitic anodes in Lithium-Ion batteries with its high theoretical capacity of 3572 mAh/gram. A large number of routes to design silicon-based anodes continue to be explored. However, many of these methods are limited by their complex procedure, expensive raw materials, and low yield of active material. A few other methods require significant energy consumption and highly toxic precursors.

Current Invention

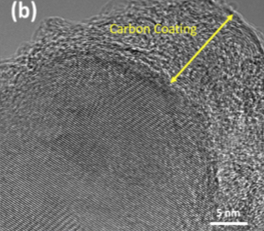

Researchers led by Profs. Cengiz and Mihrimah Ozkan pursued the development of technology that could turn these waste glass containers into high purity Silicon nanoparticles for Lithium-ion batteries. The novel, patent pending technology converts crushed waste glass bottles into highly pure and interconnected network of Silicon nanoparticles through magnesiothermic reduction. The silicon nanoparticles are then conformally coated with a carbon layer.

Schematic illustration of the Magnesiothermic reduction with NaCl as heat scavenger.

Transmission electron microscopy image of gSi@C nanoparticles with conformal carbon coating

Advantages

In addition to the recyclability and sustainability benefits, the novelty of their innovation is:

Suggested uses

Lithium-ion batteries used in:

- Electric Vehicles and Plug-in Hybrid Electric Vehicles

- Drones

- Smart phones

- Consumer electronics

State Of Development

Coin cells using the gSi@C as anode material have been assembled. Testing of these coin cells outperformed traditional batteries and demonstrated excellent electrochemical stability with a capacity of ~1420 mAh/gram after 400 cycles at a C/2 rate.

Related Materials

Other inventions by Prof. Cengiz Ozkan

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

Lithium-ion battery, Lithium Silicon battery, Silicon anode, Carbon coated silicon, Magnesiothermic reduction, Silicon nanoparticles, Waste glass bottles