Stable Photonic Structures

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 9,734,946 | 08/15/2017 | 2011-315 |

Full Description

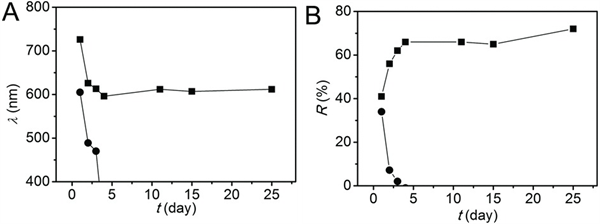

Background Colloidal assembly of photonic materials has become one of the most powerful routes for the fabrication of responsive photonic crystals. Inclusion of superparamagnetic (SPM) components into colloidal building blocks allows for effective control over the photonic properties by using external magnetic fields. The key to this self-assembly strategy is the establishment of a balance between the magnetically induced dipolar attraction and the repulsions resulting from the suffer charges or other structural factors. Strong electrostatic repulsions can be established by covering the surfaces of SPM particles with a highly charged electrolyte (e.g., sodium polyacrylate). Over time the photonic properties degrade due to the partial detachment of the polyacrylate molecules from the surface of the SPM particles. Current Invention Inventors at UCR have successfully addressed this challenge of partial detachment to ensure the long term stability of the charges on the SPM particle surface. Inventors have developed a patented process for coating the particles with a protective layer of porous silica. By trapping the acrylate polymer chains in its network, the porous silica layer can effectively enhance the charge stability and maintain the long-range electrostatic repulsion, thus producing magnetically tunable photonic structures with consistent performance even after a long period of storage. Change in (A) peak position and (B) intensity of the diffraction of aqueous solutions containing Fe3O4@p-SiO2 (square) and polyacrylate-capped Fe3O4 particles (circle) assembled under fixed external magnetic fields after the particles are stored in water for various times. For Fe3O4@p-SiO2 particles the field strength is -131G and the field gradient 77.5 G/cm, while for the polyacrylate-capped Fe3O4 particles, the field strength is -162 G and the field gradient is 82.5 G/cm

Advantages

- Long term stability of the photonic crystals.

- Powerful route for the fabrication of photonic crystals.

- Consistent performance over time

Suggested uses

- Color display devices

- Sensors

- Encryption

- Active optical components

Related Materials

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.