Core-Shell Wrapped Sulfur Particles For Li-S Cathode Material

Full Description

Background

The global transition to electric mobility hinges on a breakthrough in battery technology. Lithium-sulfur (Li-S) batteries offer a theoretical capacity nearly 10 times higher than standard Li-ion batteries. While Li-S batteries are a promising low-cost and high-energy alternative, they are plagued by the "polysulfide shuttle" effect, where active material dissolves during cycling. This causes a drastic drop in performance. This fundamental instability has prevented Li-S technology from realizing its market potential.

Innovation

Inventors at UCR, led by Prof. Cengiz Ozkan, have developed a novel cathode material composed of sulfur particles encapsulated in a nano-scale shell of silica (SiO2). Created through a simple and scalable wet chemical process, this core-shell structure physically traps the intermediate polysulfide which causes battery degradation. The protective silica acts as a barrier, preventing the loss of active material while allowing the lithium ions to move freely. This free movement of lithium ions and the prevention of the loss of active material dramatically enhances the battery's cycle life and stability.

Schematic illuatration of the two-step, wet chemical synthesis of silica coated sulfur particles (SCSPs).

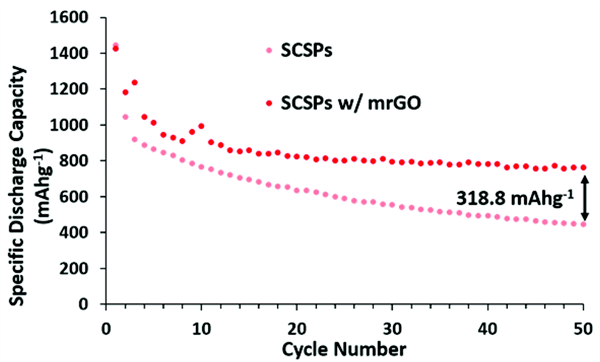

Graph showing a comparison of discharge cycle capacity of SCSPs with and without mildly reduced graphene oxide (mrGO).

Advantages

- The technology demonstrates a high specifc capacity of over 700 mAh/g after 50 cycles, far exceeding conventional lithium-ion battery cathodes.

- The silica shell significantly improves cycling stability by mitigating the polysulfide shuttle which is the primary cause of capacity fade in Li-S batteries.

- The technology uses sulfur and silica, which are both abundant and significantly cheaper than cobalt and nickel used in traditional lithium-ion batteries. This significantly reduces manufacturing cost.

- The technology is based on a facile, room-temperature, two-step, wet chemical synthesis process that can be easily scale for industrial production.

Suggested uses

- Electric vehicles

- Consumer electronics

- Grid-scale energy storage

- Light weight, high energy density batteries for drones

Inventor Information

- Please review all inventions by Prof. Ozkan and his team at UCR

- Please read recent news coverage of the Ozkans at UCR

Related Materials

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 11,362,335 | 06/14/2022 | 2015-079 |

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

cathode material, core-shell structure, cycle stability, polysulfide shuttle, electric vehicle, energy storage, high capacity battery, lithium sulfur battery, low cost manufacturing, silica coating