Method for High-Yield Chemical Recycling of Plastic Waste

Tech ID: 33370 / UC Case 2023-9AG-0

Background

Exponential plastic production and low plastic recycling rates are increasing plastic waste with negative environmental impacts. Pyrolysis is the most common method breaking down plastics, but this process results in poor yields of low value pyrolytic crude oil. Hydrotreating plastic waste with a catalyst is an emerging method to generate low molecular weight alkanes from plastic waste. Though promising, only a few catalysts are currently available for this reaction.

Brief Description

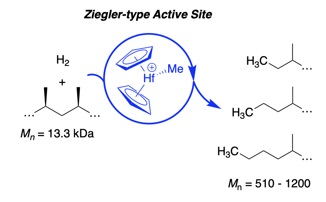

Professor Matthew Conley from the University of California, Riverside has discovered that catalysts used to generate polyolefin plastics also perform well in hydrotreatment reactions of plastic waste. This method works by treating plastic materials with known catalysts at 200⁰C to degrade polymers into smaller alkanes in the presence of hydrogen. This technology is advantageous compared to existing methods since it does not require high temperatures, has a relatively high yield (+80%), and can be applied to a variety of plastics to generate a feedstock of smaller polymers and monomers for further processing.

Application

- Catalysts may be used to degrade plastics into smaller aliphatic fragments. These fragments can be used as fuels, lubricants, or converted back to plastics by subsequent processing to the monomer.

Patent Status

| Country | Type | Number | Dated | Case |

| Patent Cooperation Treaty | Published Application | WO 2024/254526 | 12/12/2024 | 2023-9AG |

Additional Patent Pending

Related Materials

Contact

- Grace Yee

- grace.yee@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

polyolefin catalysts, Ziegler-Natta catalysts, plastic recycling, petroleum processing, polymer degradation