Pulsed Laser Deadhesion

Full Description

Background

For substrates held together by weak adhesion, de-bonding can be achieved by physical separation. Strategies for de-bonding substrates held together by strong adhesives usually rely on thermal, chemical or mechanical methods. These methods often require that the glued pieces be exposed to high temperature or harsh solvents. Light provides a non-thermal input for de-bonding adhesives. Most strategies for light-induced de-bonding require the use of custom-made photosensitive adhesives. These custom-made glues are expensive, lack the strength of commercial glue formulations and have slow response times - on the order of minutes.

Technology

Prof. Chris Bardeen and his team at UCR have developed a one-step de-bonding process that uses high intensity light that can separate substrates and does not use any special additives. The technology is insensitive to the adhesive and is capable of de-bonding in a controlled and reproducible manner without damaging the bonded surfaces. All that is required is that one of the substrates be transparent in some region of the light spectrum.

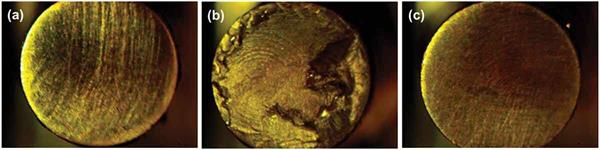

Optical microscopy images of (a) metal surfaces before glueing; (b) metal surface after physical de-bonding leaving residual adhesive and debris; and (c) metal surface after de-bonding with light with minimal residue.

Advantages

- One-step de-bonding with minimal damage to the substrates and there are no waste/byproducts.

- Insensitiv to the nature of the adhesive or applied force.

- The adhesive bond fails within milliseconds of the arrival of the light pulse.

- Unlike prior approaches, no specialized photosensitive additives are required.

- Compatible with most commercially available adhesive formulations.

- Ability to controllably and reproducibly turn off strong adhesion.

Suggested uses

A wide variety of applications that require clean and quick de-bonding - for example, solar panel recycling, semiconductor/chip fabrication, cosmetics, aerospace, etc.

State Of Development

Demonstrated lab-level, proof-of-concept prototype for a a few different applications.

Inventor Information

- Please visit Prof. Bardeen's research group website to learn more about their research.

- Please review all inventions by Prof. Bardeen and his team at UCR.

Related Materials

Patent Status

Patent Pending

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

adhesive de-bonding, light pulse, laser pulse, rapid de-bonding, semiconductors, chip fabrication, explosive bolts, solar panel recycling