Continuous Process to Synthesize Size and Morphologically Controlled Nanostructures for Energy Storage

Background

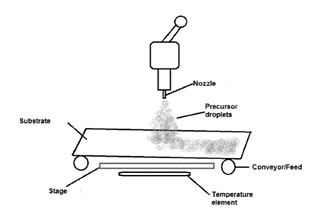

Researchers at UCR have developed a flexible and affordable solution based synthesis process for manufacturing LiFePO4 (LFP) and other nanostructures at low temperatures (150 to 200 oC) with highly reproducible sizes and shapes. The nanocrystalline structures may be incorporated into cathodes and anodes to enhance charging cycle stability or enhance capacitance (when doped with conductive metals).

The process is run at relatively low temperatures, and uses environmentally friendly solvents that transport precursor to flexible conductive substrates. This results in lower up front and ongoing manufacturing costs in cathode and anode production. Control over the material parameters is maintained through altering the solution parameters. The produced structures are uniformly dispersed and retain homogeneity in size and shape (vs. traditional high temperature solid state synthesis methods), preventing loss of performance and capacity due to increased stresses and charge de-stabilization which occur with heterogeneous particle sizes.

Application

This low cost, environmentally friendly, and low temperature process may be used in the scalable manufacture of batteries for use in renewable energy and power grid storage.

Related Materials

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 9,666,857 | 05/30/2017 | 2013-250 |

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

lithium ion, low temperature, precision, energy, storage, battery, anode, cathode, morphology, renewable, LFP, LiFePO4, nanostructures, nanocrystalline