Software for Automated Microfluidic Chip Design

Background

Microfluidics devices for biological research and clinical applications allow for the manipulation and analysis of biological samples and use low amounts of sample and reagent. The ability to use less sample and reagent lowers laboratory and clinical costs. In addition microfluidic devices allow for the automation of a variety of manual tasks in the lab or clinic.

One building block of the microfluidic chip is the integrated microvalve. Microvalves can be combined to form components, and fully functional integrated biochips can then be designed as a collection of interconnected components. At present, this design process is carried out by hand using software (e.g., AutoCAD) which is tedious, time-consuming, and prone to error.

Brief Description

Professor Brisk’s research group at the University of California, Riverside, has developed software to design and analyze an entire microfluidic chip. This is done using Microfluidic Design Automation (MDA) software to synthesize and physically lay out the devices.This software uses Microfluidic Design Automation (MDA) to physically render chips. This approach is similar to Electronic Design Automation (EDA) in the semiconductor industry. The software automatically creates a chip architecture that is converted to MHDL, a human-readable microfluidic hardware design language, enabling manual refinement. When the chip designer is satisfied with the architecture, the software physically lays out the different layers of the chip. The output is an AutoCAD DXF (or other vector graphics) file that can be transferred to a foundry for fabrication.

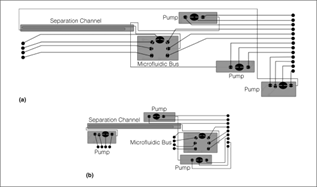

Fig. 1 shows a microfluidic device layout designed and laid-out by the UCR software.

Application

- Allows for the quick and efficient design of microfluidic devices.

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 10,360,336 | 07/23/2019 | 2016-189 |

Related Materials

Contact

- Grace Yee

- grace.yee@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

microfluidics, routing algorithm, planar placement, lab-on-a-chip, LoC, chip design