LiDAR-based Hatch Localization for Loading/Unloading Cargo

Full Description

Background

Transloading is the process of moving cargo from one mode of transportation to another. Automation of transloading requires accurate locations for hatch (the opening in the top of the train car or ship used for loading and unloading) edges and bulk cargo pile surfaces. The duration of complete transloading is long during which the hatch location changes over a sequence of cycles - requiring accurate tracking of hatch location as it changes. For successful automation of transloading, the scanning system needs to have high resolution, and work both in day and night conditions.

Technology

Researchers at UC Riverside have developed a novel system for automatically locating the edge of a hatch using light detection and ranging (LiDAR) sensor mounted on a pan-tilt unit on cranes used for transloading. Computations complete in less than 5 milliseconds after the LiDAR scan completes, which is well within the time constraints imposed by the crane transloading cycle. The team successfully demonstrated the system's robustness, reliability and accuracy.

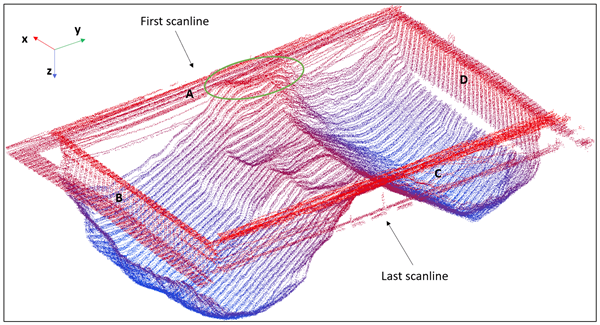

Example of a voxelized point cloud after swipe scanning in a nearly full hatch scenario. The bulk cargo was stacked above the hatch edge in the green ellipse area.

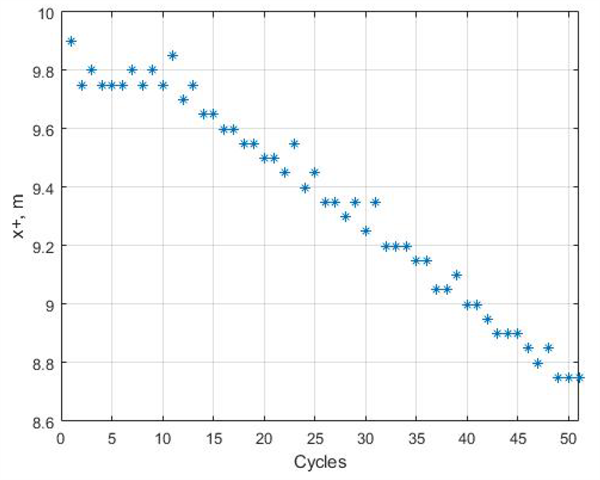

Sample of hatch edge position over several cycles

Advantages

The significant features of the developed software system are:

- Fast processing time allowing the system to determine the hatch location within the time that it takes the crane to complete one cycle of loading or unloading.

- Works with empty to nearly full hatches which is challenging because the cargo can obscure the hatch edges.

- Accurately tracks hatch movement

- Significantly improves safety and efficiency of hatch loading or unloading process.

Applications

- Safe and efficient cargo handling

- Automation of crane operations

- Improve safety and enhance efficiency of transloading operations

State of Development

The team conducted experimental trials for hundreds of cycles and demonstrated the ability to track the hatch location as it moves. The accuracy and reliability of the software solution is significant - standard deviation of less than 0.30 m and the worst case error is less than 0.35 m - for a hatch that is typically 30 m.

Related Materials

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

LiDAR, crane transloading, hatch localization, cargo handling, transloading automation, hatch movement tracking