One-Step Synthesis of Aligned Nanoparticles With High Purity

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Published Application | 20240157442 | 05/16/2024 | 2021-814 |

Full Description

Background

The demand for devices and composites based on metal nanoparticles have fostered the development of scalable, synthetic approaches that can assemble metal nanoparticles into well defined structures and arrangements. Gas-phase synthesis is particularly attractive as they allow for continuous production and also do not need surfactants or ligands. A major limitation of existing gas-phase synthesis methods are the difficulties in directing the assembly of metal nanoparticles in a controlled manner thus limiting the architecture and structure modulation.

Traditional colloidal phase synthetic routes use surface capping to stabilize metal nanoparticles and prevent irreversible random aggregation. These techniques, however, are multi-step and involve ligand, surfactants and hazardous solvents - thereby limiting their scalability.

Technology

Researchers at UCR, led by Prof(s). Zachariah and Abbaschian have developed an electromagnetic levitation technique to generate metal nanoparticles and tune their aggregate structure and morphology. This technique uses magnetic fields to levitate and inductively heat metal pieces, that result in metal evaporation and formation of nanoparticles in the gas phase. The team has successfully demonstrated their technique in the lab with ferromagnetic metals such as iron, nickel and copper. They have observed that for these metals the magnetic field interacts with the generated particles to form chain assemblies composed of <20 nm particles.

Schematic illustration of the on-the-fly formation and directed assembly of metal nanoparticles from electromagnetically levitated metal droplets. Different aggregate structures are accessible.

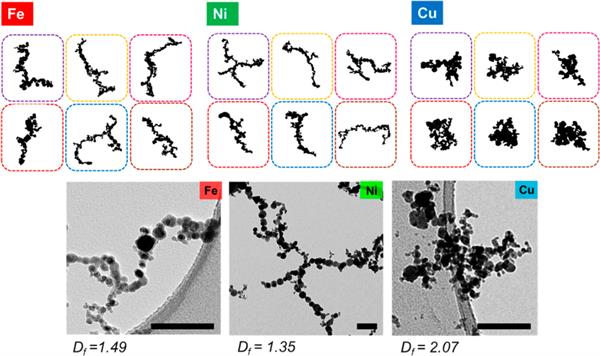

The typical aggregates and the corresponding fractal dimensions (Df) of Fe, Ni and Cu obtained from their respective metal droplets.

Advantages

- The developed electromagnetic levitation process is a single step, continuous process and generates assemblies of high purity nanometals.

- The process does not involve the use of hazardous solvents and is ligand and surfactant free.

- The technique is facile and is scalable to generate large quantities of metal particle assemblies.

- Estimates suggest a significant reduction in production times and manufacturing costs.

Application

Metal nanoparticles fabricated with this method may be used in

- Opto-electronics

- Biomedical imaging

- Sensors

- Catalysts

- Filtration and purification materials.

Related Materials

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

nanoparticles, alignment, morphology, synthesis, electromagnetic levitation