Passive Elastomeric Valves for Microengines that Allow, Block, And Limit Fluid Flow In One Or More Directions

Background

Millimeter scale internal combustion engines can conceivably be used to replace a battery in effectively any small portable powered system. Liquid hydrocarbon fuels hold 300 times the energy per weight unit than a NiCad battery and 100x that of a Li-ion battery. Such systems would not require charging, but changing of a fuel capsule that can occur instantaneously. Many polymer combustion micro-engines (e.g. ~1-gram combustion engines) rely on external systems to control valve function. Such systems include human control or active valves that open or close at predetermined times. These auxiliary systems can be far larger and heavier than the micro-engine itself, which limits the broader utility of the micro-engine. Current passive microfluidic valves are check valves - they allow flow in one direction, but block flow in the other and are impractical for most applications.

Technology Description

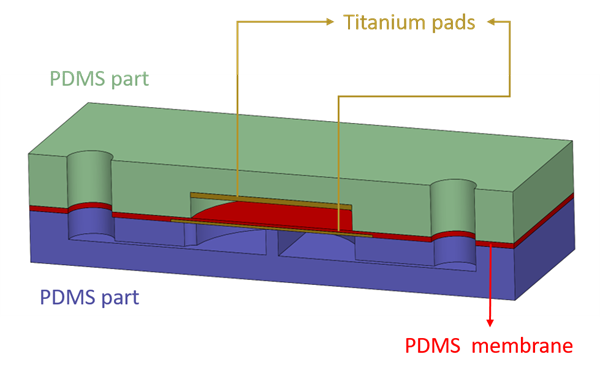

A UC Santa Cruz researcher has designed a valve system for a microengine that has a broader range of functions than current solutions but lacks external control systems or active components. The system features microfluidic valves that allow, modulate, and/or block flow based on predetermined system parameters (e.g., flow rate or pressure differences). The valves require little to no logic control and preserve functionality and substantially reduce the size of external valve units. The valves include passive components that modulate the flow of liquids and gasses through channels. The valves include channels, membranes, and holes configured to allow or block flow in one or both directions based on flow properties (flowrate and pressure state) within the system. Fabrication of elastomeric valves can be performed using soft lithography, molding, manual processing, and plasma bonding. The valves can allow, modulate, or block flow based on predetermined selected system parameters such as flow rate or pressure difference and can allow or block flow in the reverse direction. Such characteristics are necessary to control combustion reactions at a small scale.

Applications

Advantages

Intellectual Property Information

| Country | Type | Number | Dated | Case |

| United States Of America | Published Application | 20220136618 | 05/05/2022 | 2020-295 |

Related Materials

Contact

- Marc Oettinger

- marc.oettinger@ucsc.edu

- tel: View Phone Number.

Inventors

- King, Natalie

- Lin, Keng-yu

- Wehner, Michael

Other Information

Keywords

Micro-engine, Microfluidics, Microfluidic valve, Passive valve, Combustion