Silicon Nanofiber Paper Battery

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 10,211,449 | 02/19/2019 | 2014-810 |

Full Description

Background

High theoretical capacity, availability abundance, non-toxicity and environmental benignity make Silicon (Si) the preferred choice of anode for next generation Lithium-ion batteries. Large volumetric expansion (~300%), achievement of Si nanostructures (characteristic dimension below 150 nm) and pragmatic fabrication process are critical obstacles to overcome to build Lithium-Silicon batteries for real world applications. Electrospinning of polymers, dissolved in organic solvents along with active material such as Si, is a feasible fabrication process. However, current electrospinning methods:

- Require lengthy, thermal oxidative stabilization and carbonization steps.

- Build electrodes with reduced capacity because the weight percentage of active material can be less than 50%.

Current Invention

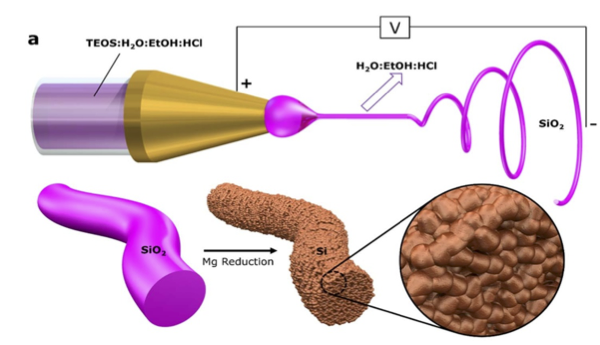

Prof. Cengiz Ozkan and his research team have developed a patented, binderless, freestanding, Silicon Nanofiber (SiNF) paper with Si weight percentage in excess of 80%. SiNF paper is synthesized via magnesiothermic reduction of SiO2 nanofiber (SiO2NF) paper which is produced by an in situ acid-catalyzed polymerization of tetraethyl orthosilicate (TEOS) in flight. To enhance the surface conductivity of the electrode, a 4 nm carbon coating is applied to the SiNF paper.

Schematic illustration of the electrospinning and the subsequent reduction process.

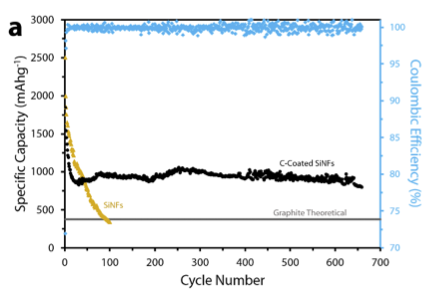

Cycling data for carbon-coated SiNF compared to uncoated SiNF at C/10 rate.

Advantages

The novel aspects and benefits of their invention are:

Suggested uses

Testing

The team fabricated 2032 type coin cells with SiNF electrodes. After 650 cycles, the SiNF electrodes deliver a reversible capacity of 802 mAh/gram and a coulombic efficiency of 99.9%.

Related Materials

Contact

- Venkata S. Krishnamurty

- venkata.krishnamurty@ucr.edu

- tel: View Phone Number.

Other Information

Keywords

Lithium ion battery, Lithium Silicon battery, Silicon Nanofiber, Paper battery, Renewable energy, Magnesiothermic reduction, Electric Vehicles