A Self-Regenerative Hybrid Tissue Structure For 3D fabrication of heart valves, blood vessels and other constructs / Mesh enclosed tissue constructs

Brief Description

Current tissue engineered constructs face drawbacks such as structural vulnerability, functionality, and a lack of mechanical properties. A continual need for a tissue constructs that can resist the physiological forces within the body, while being biocompatible, persists.

Researchers at UC Irvine have developed a tissue construct composed of a multi-layered tissue enclosed on a metal mesh that addresses the drawbacks experienced by other developed solutions.

Full Description

Engineering membrane-like tissue structures with the ability to remodel and regenerate is currently an unresolved subject in the field of tissue engineering. Attempts to create functional membrane tissues have exhibited limited success. Drawbacks include structural vulnerability, short term functionality, and limited mechanical properties of the membrane constructs. Here, researchers at UC Irvine have addressed these problems by developing a scaffold capable of supporting cell growth and renewal for tissue engineering applications.

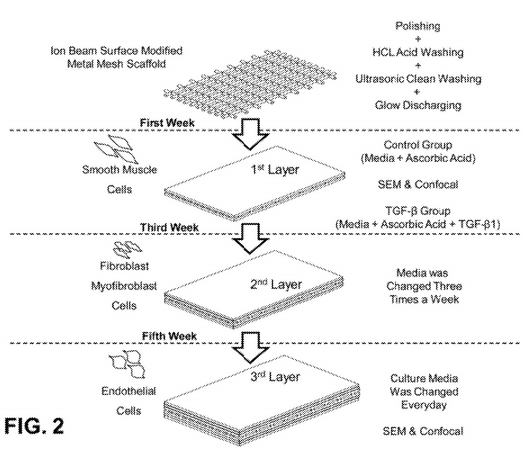

The scaffold consists of layers of a woven mesh material that is enclosed tightly by a multi-layer biological matrix. Total envelopment of the mesh by the cell layers allow the scaffold to retain all the advantages of using biological scaffolds while developing a strong extracellular matrix (ECM) backbone that can withstand various types of load inside the body. The mesh pattern is advantageous because it ensures structure integration of the formed tissue and allows cells and ECM components on both sides of the mesh to interact with each other. This method of fabricating one of these tissue constructs is show in Fig. 2.

Briefly,

it involves preparing the mesh scaffold. The mesh is heated and water quenched.

The oxidized film was removed through polishing, washing, and glow discharging.

After cleaning, ion beam surface modification method was used to get a smooth

surface, ensure biocompatibility, and enhance cell attachment onto the mesh

surfaces. After polishing, the meshes are washed, irradiated with ion beam

energy and then seeded with cells. Prior to cell seeding, the mesh can be

coated with growth factors and materials.

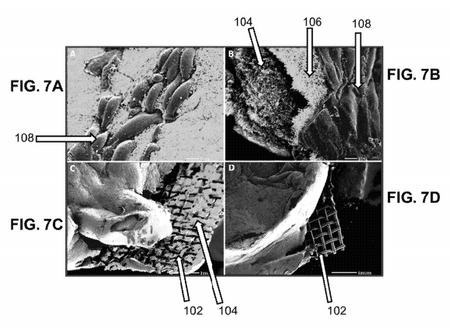

Figure 7 show SEM images

taken after eight weeks, depicting the three layers of tissue tightly enclosing

the stainless steel mesh.Fig.

7A shows the endothelial surface layer, the smooth

structures 108, covering

the construct in a confluent manner. FIG.

7B shows that after eight weeks, the tissue shows three

different cell layers in sequence, 108 is the surface endothelial layer, 106 is the middle fibroblast and

myofibroblast layer, and 104 is the base layer of smooth muscle

cells. FIG. 7C and FIG.

7D show that the mesh 102 is tightly integrated with the tissue

membrane, with FIG. 7C further illustrating that the cells 104 are penetrating through the mesh 102 opening holes. It can be observed that

adding the second and the third layers improves production of the ECM (mainly

collagen and glycosaminoglycans) that covers the mesh, forming a confluent

smooth surface with endothelial cell lining in both experimental groups.

Suggested uses

The mesh scaffold can be formed into customized shapes. This invention is suitable for applications where a strong tissue construct is desired, for example heart valves and vascular grafts.

Advantages

The invention is an interwoven mesh scaffold for the 3D fabrication of a tissue construct. The key advantages of the mesh scaffold arise from its interwoven nature: it allows the scaffold to withstand the physiological forces inside the body and its porosity lets cells fully envelop the mesh scaffold, thereby making the scaffold biocompatible. Furthermore, the woven mesh allows cells to interact with each other and continuously renew and organize to develop a living tissue construct.

Patent Status

| Country | Type | Number | Dated | Case |

| United States Of America | Issued Patent | 10,610,616 | 04/07/2020 | 2011-607 |

| United States Of America | Issued Patent | 9,925,296 | 03/27/2018 | 2011-607 |

| United States Of America | Issued Patent | 8,936,650 | 01/20/2015 | 2011-607 |

| United States Of America | Issued Patent | 8,900,862 | 12/02/2014 | 2011-607 |

| United States Of America | Published Application | 20150081012 | 03/19/2015 | 2011-607 |

Contact

- Alvin Viray

- aviray@uci.edu

- tel: View Phone Number.